Dynamic and Static Weighing

Underbody Weighing System

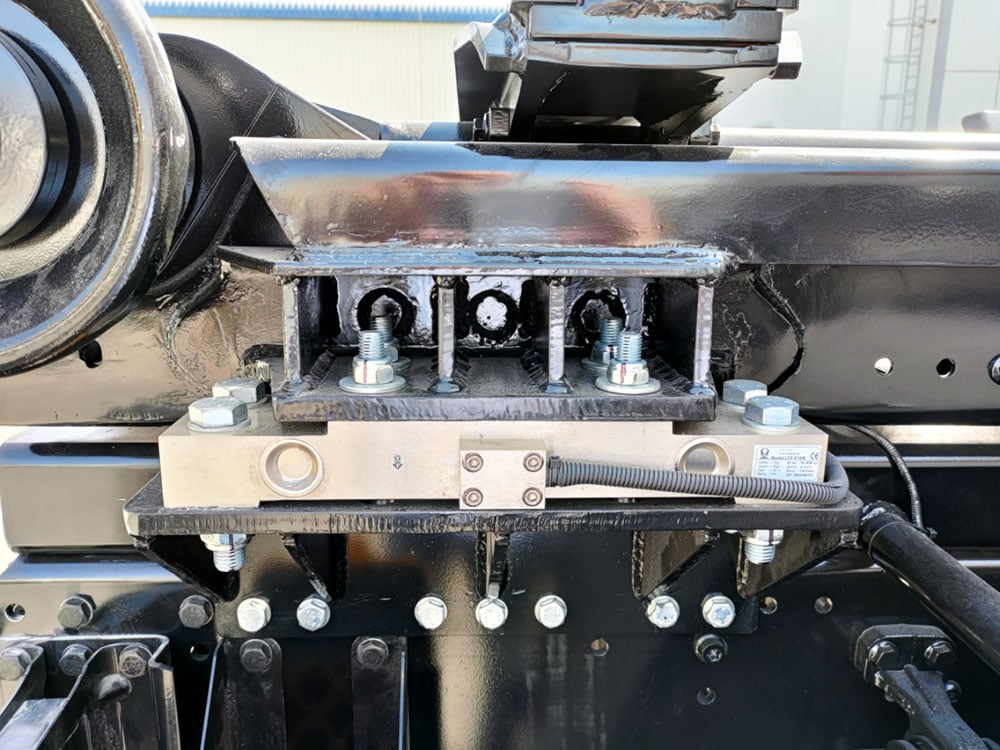

The system called “Underbody” is available in configurations with 4, 6 or 8 load cells depending on the type of vehicle. The “Underbody” system is built by placing the load cells between the frame and the tank of the compactor truck. The underbody weighing system is made up of load cells, a weight indicator mod. VLF Pro and an antenna for reading the container tags.

The load cells are mounted between the chassis and tank by a low profile brackets which has minimal body height modifications to provide a very accurate weight while maintaining vehicle stability/safety.

Underbody Weighing System

Lateral Bin Lifter

The system called “Lateral Bin Lifter” is a dynamic weighing system that allows you to weigh the container during the emptying cycle without interrupting the lifting operation. The system is built by installing 2 load cells on the lifting arms and 2 proximity sensors which determines the correct position in which to detect the gross weight and subsequently the bin tare.

In this way the net weight of each bin is calculated and associated with the tag number. The rear bin lifter weighing system is made up of 2 load cells, a weight indicator mod. Extreme 737, 2 proximity sensors and an antenna for reading the bins tags.

Lateral Bin Lifter

Crane Lifter

The system called “Crane Lifter” is a dynamic weighing system that allows you to weigh the container during the emptying cycle without interrupting the lifting operation. The system is built by installing 1 load cells on the Hydraulic lifting arm and 2 proximity sensors which determines the correct position in which to detect the gross weight and subsequently the bin tare.

In this way the net weight of each bin is calculated and associated with the tag number. The crane lifter weighing system is made up of 1 load cells, a weight indicator mod. Extreme 737, 2 proximity sensors and an antenna for reading the bins tags.

Crane Lifter

Rear Bin Lifter

The system called “Rear Bin Lifter” is a dynamic weighing system that allows you to weigh the container during the emptying cycle without interrupting the lifting operation. The system is built by installing 2 load cells on the lifting arms and an inclinometer which determines the correct position in which to detect the gross weight and subsequently the bin tare.

In this way the net weight of each bin is calculated and associated with the tag number. The rear bin lifter weighing system is made up of 2 load cells, a weight indicator mod. Extreme 737, an inclinometer and an antenna for reading the bins tags.

Rear Bin Lifter

Front Bin Lifter

The system called “Front Bin Lifter” is a dynamic weighing system that allows you to weigh the container during the emptying cycle without interrupting the lifting operation. The system is built by installing 2 load cells on the lifting arms and an inclinometer which determines the correct position in which to detect the gross weight and subsequently the bin tare.

In this way the net weight of each bin is calculated and associated with the tag number. The rear bin lifter weighing system is made up of 2 load cells, a weight indicator mod. Extreme 737, an inclinometer and an antenna for reading the bins tags.

Front Bin Lifter

Skip Lifter

The system called “Skip Lifter” can be built by static or dynamic weighing system. The system is built by installing 2 load cells on the lifting arms and an inclinometer which determines the correct position in which to detect the gross weight, or installing 4 or 6 load cells on the frame. The skip bin lifter dynamic weighing system is made up of 2 load cells mod. LE7-K6M, a weight indicator mod. Extreme 737, an inclinometer and an antenna for reading the bins tag.

The skip bin lifter static weighing system is made up of 4 or 6 load cells, a weight indicator mod. VLF Pro and an antenna for reading the skip tag.

Skip Lifter

DriveMy.Zone Cloud Software

Discover Products

Wide range of load cells for easy mounting on any type of waste compactor. From Front Loader models, to side loaders, to rear loaders, to hook loaders and skip loaders

Weight indicators specifically designed to optimize waste collection. Our range covers use for static systems (underbody), and dynamic (Non Stop Weighing) bin lifters. All rigorously certified NAWI & AWI

Everything you need to best optimize waste collection and fleet management. From the simple printer to the most sophisticated monitoring systems via GPRS and related data collection/processing

DriveMy.Zone

DRIVEMY.ZONE is a software for the unified management of all waste collection operations and route organization, below are some features:

Waste weight in real time

receive all the bin weights in real time in the application

Complete fleet management

Weight loaded in real time

Organize collections like never before

Alarms & Events

Receive real-time alerts from the vehicle, for example if there is a mechanical problem, if the speed is too high, if the vehicle is out of the zone, and much more

Remote Analysis

Analyzes all the data received from vehicles and bins with our analysis systems

API enabled

Connect your software or your ERP and receive all the data within your management software

Efficiency and Traceability

Improve running costs with DriveMy.Zone tools and help improve environmental sustainability with the ECO Drive system